Kosteneffectieve aardgasdroging voor verbeterde calciumsilicaatplaatproductie

Productdetails:

| Plaats van herkomst: | CHINA |

| Merknaam: | OSMANUV |

| Certificering: | ISO9001 |

| Modelnummer: | OSM-LRHG-1320T |

Betalen & Verzenden Algemene voorwaarden:

| Min. bestelaantal: | 1 set |

|---|---|

| Prijs: | Bespreekbaar |

| Verpakking Details: | Houten verpakking |

| Levertijd: | 35 dagen |

| Betalingscondities: | T/t |

| Levering vermogen: | Onderhandeling |

|

Gedetailleerde informatie |

|||

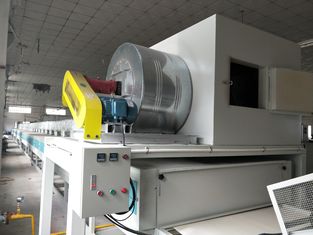

| Productnaam: | 28 meter aardgasdroogmachine | Dimensie (L*W*H): | Aangepaste grootte, 28000 mm * 2400 mm * 3140 mm |

|---|---|---|---|

| Stroom: | 24 kW | Spanning: | 380V/50Hz |

| Coatingbreedte: | 1320mm | Coatingsnelheid: | regelbaar, 0,5-8m/min |

| Garantie: | 1 jaar | Voorwaarde: | Nieuw |

| Markeren: | Gasdrogemachine,industriële calciumsilicaatplaatdroger,kosteneffectieve gasdroogapparatuur |

||

Productomschrijving

Kosteneffectieve Natuurgasdroging voor Verbeterde Productie van Calciumsilicaatplaten

Productbeschrijving

Deze aardgasdrooglijn is speciaal ontworpen voor calciumsilicaatplaten en zorgt voor een gelijkmatige warmteverdeling en nauwkeurige temperatuurregeling gedurende het droogproces. Het systeem garandeert een optimale vochtverwijdering met behoud van de integriteit en dimensionale stabiliteit van de platen.

Technische Parameters

| Parameter | Specificatie |

|---|---|

| Model |

OSM-LRHG-1320T |

| Warmtebron | Aardgasbrandersysteem |

| Maximumtemperatuur | 300°C |

| Transportbandbreedte | 1320 mm (Aanpasbaar) |

| Droogzones | 6 zones (Aanpasbaar) |

| Brandstofverbruik | 15-25 m³/u |

| Besturingssysteem | PLC + HMI Touchscreen |

Toepassing

Drogen en uitharden van calciumsilicaatplaten, brandwerende panelen en architecturale plafondmaterialen.

Maatwerk

-

Aanpasbaar configuratie van de droogzones

-

Aanpasbaar snelheid en breedte van de transportband

-

Aanpasbaar temperatuurprofilering

Eigenschap

-

Gelijkmatige warmteverdeling

-

Nauwkeurige temperatuurregeling

-

Energiezuinige werking

-

Robuuste constructie

Ondersteuning en Services

-

Installatiebegeleiding

-

Trainingsprogramma voor operators

-

12 maanden garantie

-

Technische ondersteuning

Verpakking en Verzending

-

Zware houten krat

-

Weerbestendige verpakking

-

Professionele exportstandaarden

FAQ

V: Wat is het energieverbruik?

A: Het gemiddelde verbruik is 18-22 m³/u, afhankelijk van de productie-eisen.